Welcome at DIPRO®!

The heart

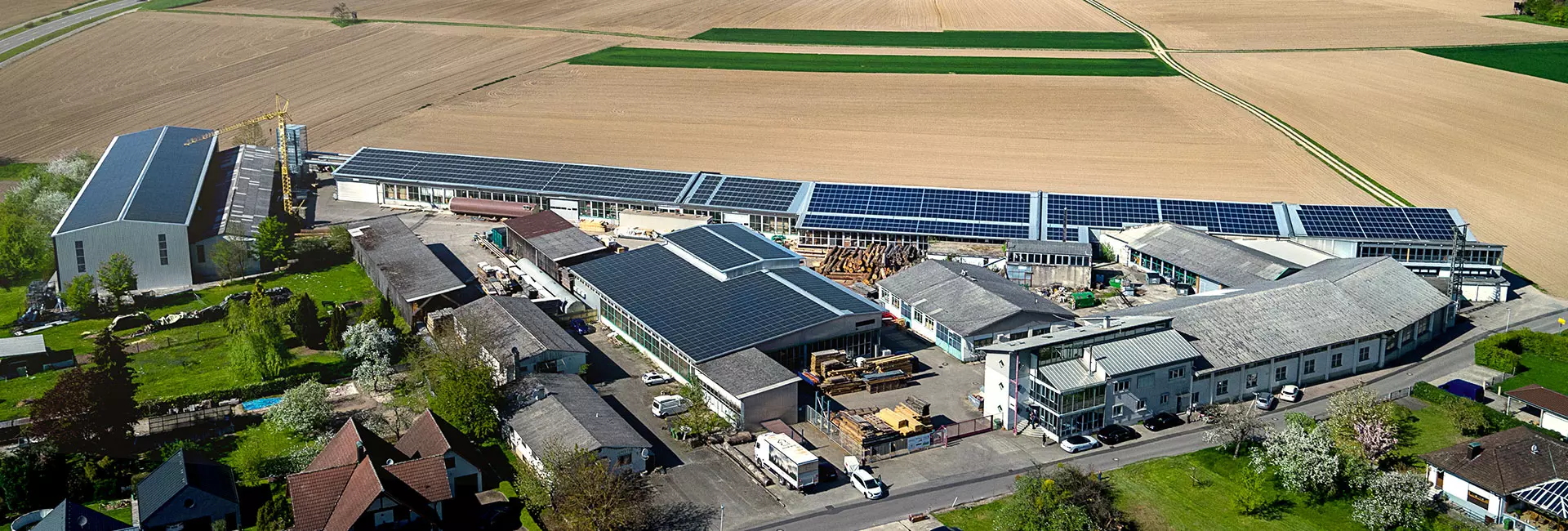

Come in and get to know our medium-sized company directly from the heart of the German region of Baden. We as DIPRO® have the mission to make the fascinating nature of the Black Forest tangible for everyone and to preserve it for future generations. We are a manufacturer of high-quality, durable solid wood boards having the entire value chain in-house. Wood, our most important raw material, is sourced here for our regional production from local trees directly from the Black Forest. Our planks are characterised by high quality, individuality and regionality and give your living space a unique character.

Our values

Our values are the heart of DIPRO®. They describe what we stand for and what we base our daily actions on. At DIPRO®, we are aware of our great responsibility to protect the environment as the most important part of our production, to treat it with respect and to preserve it for future generations. Environmental awareness is deeply rooted in our company history and part of our attitude to life. We assume responsibility towards renewable raw materials, treating them respectfully. The high-quality products that we produce with great passion are the result of our total appreciation of nature and your limited resources.

Since nature is particularly important to us and is an essential part of our work, we attach great value to excellent quality. This starts with the selection of our woods and continues throughout the entire production process. Our demands should also be reflected in your rooms and increase your well-being. Your health is particularly important to us. We spend a large part of our lives indoors and want our floorboard products to contribute to a healthier lifestyle. Therefore, we refrain from any use of harmful substances during the entire production process.